COMMERCIAL KNIVES

UNCOMPROMISING QUALITY

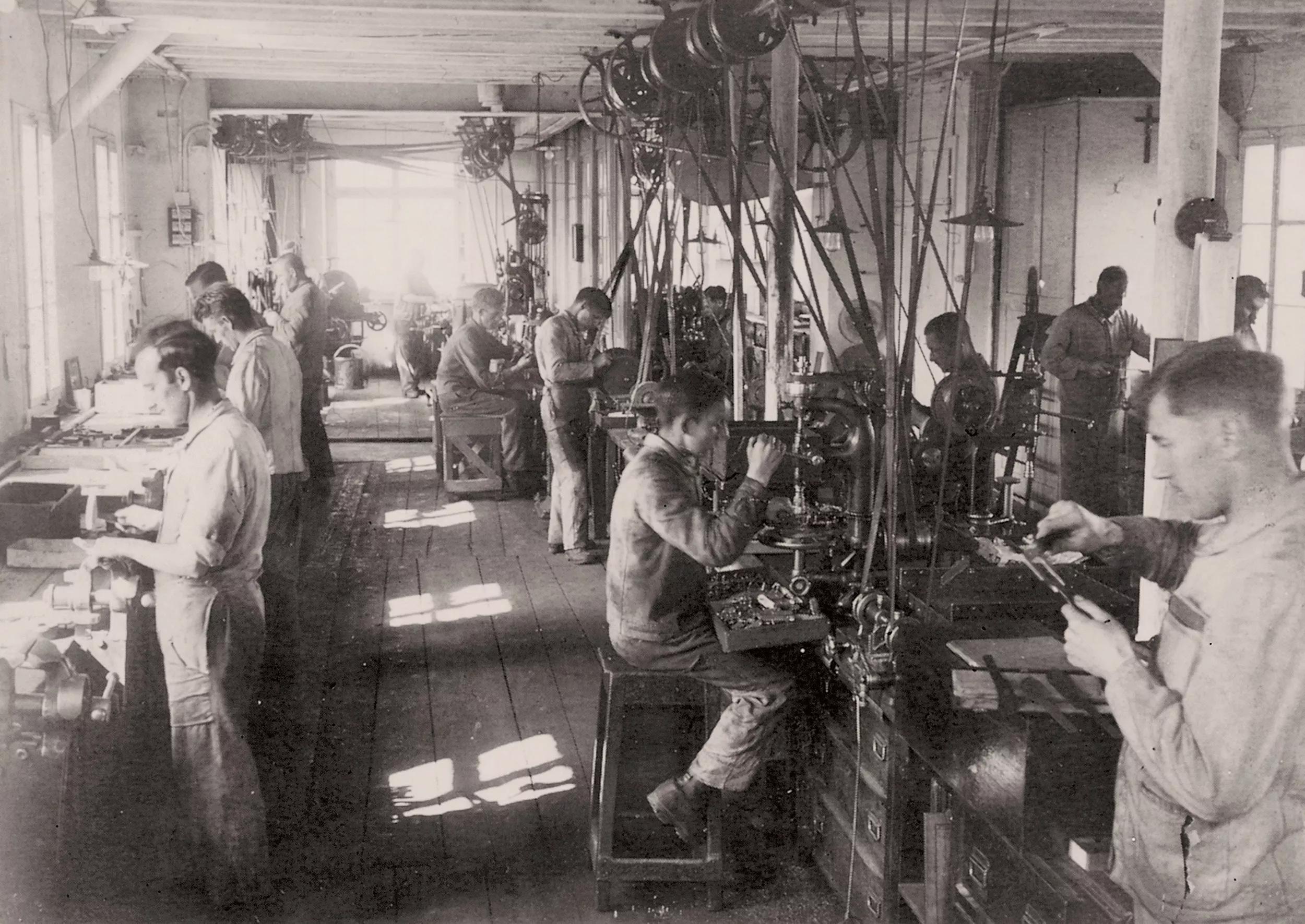

Swiss excellence and standout craftsmanship – since 140 years

- Only European high-quality steel is used

- Swiss production in Ibach and Delémont

- Swiss Made products

At Victorinox in Switzerland, we craft 90,000 household & professional knives daily – which

- stand up to the most intense workloads worldwide

- come with the most impressive blade cutting performance

- retain a cutting edge shape

- are easier to sharpen

- are perfectly balanced and ergonomically advanced

- come with professional shaped non-slip synthetic handles

All the good reasons to choose Victorinox – because like you, we do not accept compromises

KEY FACTS

Consumer Health Safety

Victorinox meets all regulations to ensure consumer health safety in the US.

1) comply with FDA regulations for food contact,

2) carry the internationally recognized NSF symbol,

3) meet the HACCP requirements.

Cutting angle

All Victorinox knives exceed the cutting angle standard according to ISO 8442-1.

Conclusion

We consistently ensure the correct cutting angle in compliance with the ISO standard. Therefore, our knives have the prescribed angle of ≤ 40°.

Each blade shape must have the ideal cutting angle and depending on the application, this angle must be smaller or larger. The smaller the angle the sharper

the knife, the sharper the knife the more unstable the blade. This is especially important because of the different applications.

Steel hardness HRC

All Victorinox knives meet the steel hardness HRC standard according to ISO 8442-1.

Conclusion

Victorinox uses a type A steel, which has a minimum requirement of 52 HRC.

We optimize and adjust the alloy and hardness of each steel blade depending on the intended use. This ensures maximum flexibility and durability in each of our knives.

It also means that each knife is made with the ideal level of edge retention and cutting performance for a specific purpose.

Further Information

Our extensive testing at incoming inspection, in production and the very tight analytical tolerances of our steels ensure that we have minimal standard deviations in hardness and other important characteristics. This ensures continuous and consistent quality in advance.

The steel grades used are produced according to our own Victorinox “recipes” and have a balanced composition of all alloying elements. These recipes have been optimized over decades.

Quality management

Victorinox achieves all this because we have,

- an incoming- , production- and final inspection

- an own steel laboratory

- tighter tolerances for cutting angles, hardness and alloys

- developed and optimized the steel for each application together with our steel manufacturers

- regular test runs with accredited laboratories assure that our testing machines are calibrated